精選產品

聯絡資訊

Libao Town Haian County,Jiangsu,China

電話:86-513-88932366

傳真:86-513-88932366

- 首頁

- 精選產品

- cnc profile rolling machine hydraulic bender steel pipe rolling machine stainless steel rolling pip

cnc profile rolling machine hydraulic bender steel pipe rolling machine stainless steel rolling pip

產品型號:w24s

產品分類:工具機產業機械 / 金屬成型工具機 / 滾圓機(彎板機)

產品特色

cnc machine rolling hydraulic bending machine steel bending machine profile rolling machine hydraulic bender

cnc profile rolling machine hydraulic bender steel pipe rolling machine stainless steel rolling pipe bending machine

W24Y Hydraulic stainless steel pipes tubes and profile and section rolling bending machine

Features

Rolls are hardened & made from high quality steel

Drive shafts are hardened and ground with double taper roller bearing support

Machine can be set up in horizontal or vertical working position

Roving foot pedal control with emergency stop

Hydraulic lateral angle guide rolls

Three rollers are powered . European quality. Can be used in both vertical and horizontal position

Compared with other machines. Advantages of the machine.

Perfectly complete pre-bending,rolled-up.Working principle: two down rollers as main driving roller.Triple geared drive,low voltage driver,low current consumption and high efficiency.

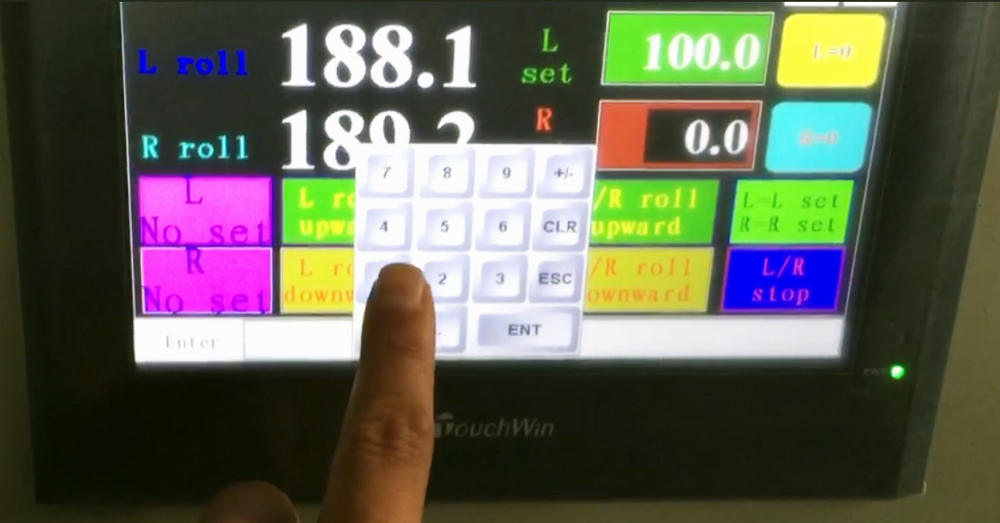

The two touch steel stick can permit the good finishing quality of asymmetric plate section bending.NC syterm,advanced and compact structure with full function.

The machine has six oil tanks(two big oil tanks,four small oil tanks),and the head is vertically.The yield strength bended profile with 320Mpa (Max.)

Both Horizontal and Vertical Working Positions.Double pinch hydraulic forming rolls.Hardened precision threadedx shafts.Dual adjustable lateral guidesRolls are driven via 3 separate hydraulic motorLower rolls hydraulic moveable up and down.

Perfectly complete pre-bending,rolled-up,roll calibrate.Working principle: two down rollers as main driving roller,or all three rollers as main driving roller,with upper roller fixed and two down rollers do up-and-town movement around one fixed center.

Triple geared drive,low voltage driver,low current consumption and high efficiency.Well hydraulic control,displacement liquid-crystal display with accuracy+_0.1mm.

Advanced technology

The two touch steel stick can permit the good finishing quality of asymmetric plate section bending.Advanced and compact structure with full function.

The machine has six oil tanks(two big oil tanks,four small oil tanks),and the head is vertically.The yield strength bended profile with 250Mpa (Max.).Full function,complicated structure,high precision and very stronger.

產品規格

| Digital Display Profile Bending Machine- W24S Serial | ||||||||

| Model&spec. | W24S-6 | W24S-16 | W24S-30 | W24S-45 | W24S-75 | W24S-100 | W24S-140 | |

| Max bending modulus of section (cm3) | 6 | 16 | 30 | 45 | 75 | 100 | 140 | |

| Bending speed(m/min) | 5.5 | 5.5 | 5.5 | 5.5 | 5 | 5 | 5 | |

| yield limit of material (MPa) | 245 | 245 | 245 | 245 | 245 | 245 | 245 | |

| inward bending of angle steel | The max cross section (mm) | 50×5 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | 150×16 |

| The min bending diameter (mm) | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | 2400 | |

| The min cross section (mm) | 20×3 | 30×3 | 35×3 | 36×5 | 38×4 | 40×5 | 50×5 | |

| The min bending diameter (mm) | 400 | 550 | 560 | 600 | 600 | 720 | 1000 | |

| outward bending of angle steel | The max cross section (mm) | 50×5 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | 150×16 |

| The min bending diameter (mm) | 800 | 1000 | 1100 | 1300 | 1600 | 1800 | 2200 | |

| The min cross section (mm) | 20×3 | 30×3 | 35×3 | 36×5 | 38×4 | 45×5 | 50×5 | |

| The min bending diameter (mm) | 400 | 550 | 500 | 600 | 700 | 760 | 400 | |

| outward bending of channel steel | channel steel model | 8 | 12 | 16 | 20 | 25 | 28 | 30 |

| The min bending diameter (mm) | 600 | 800 | 800 | 1000 | 1100 | 1100 | 1200 | |

| inward bending of channel steel | channel steel model | 8 | 12 | 16 | 20 | 25 | 28 | 30 |

| The min bending radius (mm) | 700 | 900 | 1000 | 1150 | 1600 | 1700 | 1700 | |

| plane bending of flat steel | The max cross section (mm) | 100×18 | 150×25 | 180×25 | 200×30 | 220×40 | 250×40 | 280×50 |

| The min bending diameter (mm) | 600 | 700 | 800 | 900 | 1000 | 1200 | 1300 | |

| vertical bending of flat steel | The max cross section (mm) | 50×12 | 75×16 | 90×20 | 100×25 | 110×40 | 120×40 | 150×40 |

| The min bending diameter (mm) | 500 | 760 | 800 | 1000 | 1100 | 1300 | 1500 | |

| bending of round pipe | The max cross section (mm) | 42×4 | 76×4.5 | 89×5 | 89×8 | 114×5 | 159×5 | 168×6 |

| The min bending diameter (mm) | 500 | 750 | 900 | 900 | 1200 | 2000 | 2000 | |

| bending of round bar | The max cross section (mm) | 38 | 52 | 62 | 75 | 85 | 90 | 100 |

| The min bending diameter (mm) | 450 | 600 | 600 | 800 | 100 | 1100 | 1200 | |

| bending of square pipe | The max cross section (mm) | 45×3 | 60×4 | 70×4 | 80×6 | 90×8 | 100×10 | 125×10 |

| The min bending diameter (mm) | 750 | 900 | 1000 | 1200 | 1600 | 2000 | 2500 | |

|

|

|

|

|

|

|

|

|

|

|

精選產品

-

液压闸式剪板机

-

cnc hydraulic press brake for sale

-

hydraulic press brake,hydraulic plate bending machine

-

cnc hydraulic rolling machine metal rolling machine plate roller steel plate sheet roll bend bending

-

JH21-160 metal stamping press, punching press machine, Chinese manufacturer

-

Hydraulic press four columns

-

Q35y-16 hydraulic iron workers iron worker ironworker machine punch and shears steel punching and sh